The global ‘climate change effect’ seems to pose a threat to motorists on our motorways here in New Zealand. Once upon a time, our ‘once-in-50-year flood’ arrived according to that time frame. Nowadays they seem to arrive twice a year!

The increased water volume from these floods poses an increased risk of aquaplaning to vehicles driving on motorway overpasses, as curbs and channels struggle to drain the huge amount of water.

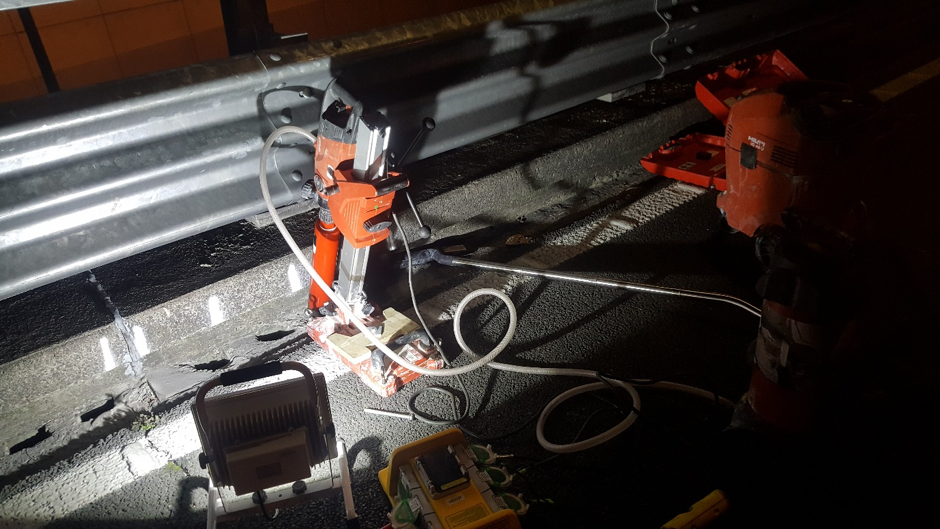

Currently, these overpass sections that allow for drainage have only two cast-in holes for water egress.It is a priority to increase the drainage of these water egress locations and so we used our specialist equipment to drill some extra holes to vie for the contract. We had to do some precision mark-outs to enable the corers to ‘set out’ for five cores at each location. The coring was certainly going to be tricky – with the coring units having to be set on an angle to avoid any reinforcing in the concrete.

While we demonstrated one precision core that did not hit any reinforcing we were not awarded the coring job. It will be up to another team to do the coring ‘set up’ to ensure the desired results. While our methodology avoided reinforcing, this may not be the methodology employed by the next team. We trust that the project is successful in correcting the issue of poor water egress reducing the aquaplaning risk to motorists.

This project delivered some very tricky coring (at night time) with the coring completed on an angle that avoided damaging any reinforcing in the concrete.