Pile Integrity Testing is essential for confirming the quality of deep foundations. This blog highlights the key requirements and often overlooked details that help ensure accurate and reliable PIT results.

Pile Integrity Testing (PIT) is a critical non-destructive method used to ensure the quality and reliability of deep foundations. Whether you’re working on bridges, high-rise buildings, or industrial projects, understanding PIT requirements is essential for structural safety and compliance.

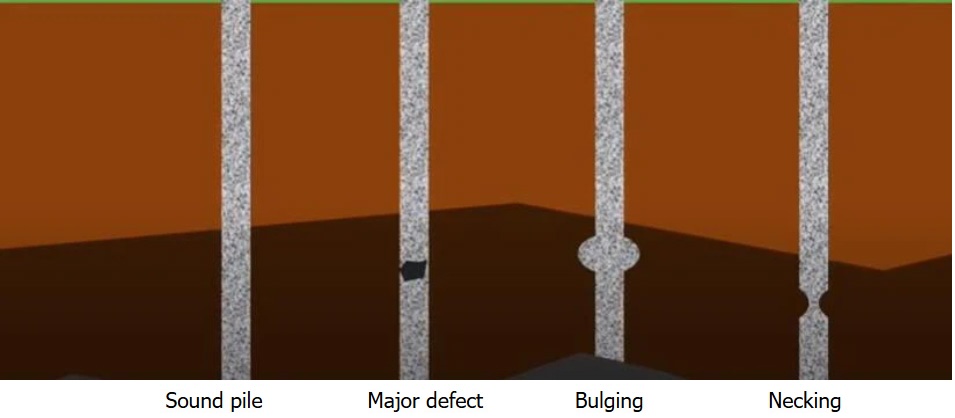

Pile Integrity Testing evaluates the physical condition of foundation piles to detect defects such as cracks, voids, necking, or inclusions. The most common method is Low Strain Impact Testing, standardized under ASTM D5882.

In this post, we want to highlight some important aspects that are lesser known and sometimes neglected.

To draw correct conclusions, it is paramount that the analyst receives the following information prior to testing:

To ensure best results, PIT must meet specific technical and procedural requirements.

Pile Integrity Testing is more than a compliance step—it’s a safeguard for structural integrity and project success. It enables engineers to detect issues early, optimize designs, and ensure long-term reliability.

Have questions about Pile Integrity Testing call CSI.

We would be keen to hear what NDT solutions you would like for your structural resilience investigations.

If you would like to find out more about the Non-Destructive Testing Services (NDT) that we offer click here!

Click here for a list of our services.

Call Us On 0800 33 77 67 Or Request a Quote Here.