Consider this scenario: Would you board a plane if you knew that the wings, turbine blades, or the fuselage had […]

Consider this scenario: Would you board a plane if you knew that the wings, turbine blades, or the fuselage had been tested for damage by an unqualified steel worker who borrowed a device from a random store around the corner? For most of us, the answer would undoubtedly be a resounding “NO.” But why should buildings and infrastructure be treated any differently? The importance of NDT in construction cannot be overstated, but it’s imperative to do your due diligence and engage the best experts in the field to ensure safety and reliability.

In the world of Non-Destructive Testing for construction we regularly encounter a wide range of misperceptions. These rank from “the devices are plug ‘n play or smart” to “they provide definite and instant answers”, to name just a couple. In other fields (like aerospace), NDT is typically a regulated profession with different levels of qualifications, and certifications. Generally, if applied responsibly and correctly NDT is a highly valuable part of a tool kit to answering questions and to making the world a safer place.

Keep reading to learn some of the most common misperceptions of NDT devices and applications we experience frequently in the field.

Ground Penetrating Radar (GPR)

Radar waves can penetrate through steel (or any other metal) – [False]

In recent times we encountered separate incidents where claims were made that GPR scanning can be used to determine the grout fill within Drossbachs.

One company even stated that “radar waves bounce within an empty duct”. Given that Drossbach ducts are manufactured from galvanised steel it is simply impossible. One only hopes that the investigated buildings are safe despite such gross negligence.

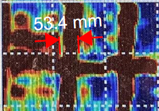

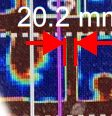

GPR can be used to retrieve bar diameter of reinforcement – [False]

It seems to be one of these urban myths that unfortunately sticks around, and we have heard this numerous times over the past 10 years. Even “evidence” was presented to us (see below).

Everyone with some experience in the field of construction would raise their

eyebrows to find such bar diameters in slabs. Great to see we can rely on our structural engineers who didn’t buy it and requested to engage CSI. Most GPR manufacturers are clear in their documentation on this subject, and state that bar diameters cannot be determined by radar.

Slab-brick wall connections

Connections between a slab and a brick wall have been detected and

marked out on site by others as can be seen in the photo below.

Pile Integrity Testing (PIT) – Low Strain Impact Pulse Echo Testing

Pit testing is suitable to evaluate a single pile – [not recommended]

We are frequently being asked to assess piles that were found to have irregularities by other testing techniques. The hope of contractors seems to be that the initial test result can be reversed or overwritten by using PIT. This is simply not within the capabilities of the technology.

PIT is a quick and relatively cheap method primarily used for Quality Assurance, although it can be used to answer some questions on existing structures. It is generally limited to evaluating the shaft above the first major non-uniformity. It can typically reveal shaft or pile defects such as major cracks, necking, soil inclusions or voids. It also can be used to determine unknown pile lengths. It is recommended to test enough piles (e.g. 20no) to determine the average or normal record so other piles can be judged against this standard. Deviant records require further evaluation.

We found that some self-proclaimed experts frequently mislabel the technologies, some examples are listed below.

– Eddy current referred to as ultrasound technology

– GPR referred to as x-ray

– Etc.

For all the mentioned technologies and techniques, although not limited to these, the following applies: The results obtained are only as accurate as the analysts understanding of the principles involved, the biggest limitation is the user.

We would be keen to hear what NDT solutions you would like for your structural resilience investigations.

If you would like to find out more about the Non-Destructive Testing Services (NDT) that we offer click here!

Click here for a list of our services.

Call Us On 0800 33 77 67 Or Request a Quote Here.