Throughout our years in the business, we have worked with many different companies, met some great people, and discussed many […]

Throughout our years in the business, we have worked with many different companies, met some great people, and discussed many topics. Like any business, it is important for us to remain aware of current trends and issues, which is why we have decided to focus our resources into Corrosion Control in New Zealand. This is a service we have provided for some time, however, during our adventures, we have learned that New Zealand is far behind other countries in regard to this issue. Many businesses and building owners are completely unaware that this is a serious matter and tend to find out when it is too late.

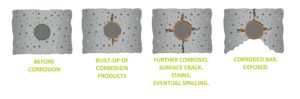

As a nation surrounded by the sea, our infrastructure is at high risk of corrosion. Steel rusts when exposed to oxygen, and even deep within a concrete structure this can occur at an alarming rate. Believe it or not, concrete is not impermeable to water. Pores in the cement and aggregate can allow liquid water to travel through even the strongest concrete. This water can carry ions such as chloride from the sea and carbonate from the atmosphere which will eventually neutralize the protection provided by concrete cover. Once the reinforcement steel begins to rust, this rust takes up a much greater volume that the original steel. This expansion causes the surrounding concrete to crack and spall, allowing more moisture to reach the reinforcement, increasing the rate of corrosion.

If corrosion is a problem or likely to become one, the good news is that it can be stopped. Oxidation is an electrochemical process that can be controlled with an applied voltage. This can be from embedded, sacrificial anodes, or from and external impressed current system. There are ways to combat this without costly repairs. The following are a few options that can help:

Corrosion Surveys

These are extremely useful as they assess the deterioration mechanisms and causes of the damage/corrosion. The surveys can consist of one or all of the following:

• Visual Inspections

• Acoustic Sounding

• Corrosion Potential

• Chloride Content Test

• Carbonation Test

• Rebar Corrosion Determination-

Sacrificial Anodes

These are used in many ways, by preventing further corrosion on buildings and bridges by application to steel reinforcement. The anodes will contain zinc, aluminium, or magnesium, which attracts rust away from the steel due to its electrode potential. The technique has been used successfully for almost a century. It is economical, reliable and can add many years to the service life of structures, saving millions of dollars. Check out our Onewa Rd project for more details.

If there is corrosion happening, leaving it unchecked or untreated can have serious and costly consequences. It may be beneficial to have someone check to see if the corrosion is serious or not. After all, as a country, we have no excuse for letting our infrastructure rust.

Looking to find out more about Corrosion Control? Get in touch with CSI at info@csiscan.nz or phone 0800 33 77 67.

Leave a Reply

You must be logged in to post a comment.