Background New Zealand has an extensive use of precast concrete particularly on buildings from 1980’s onwards. The use of precast […]

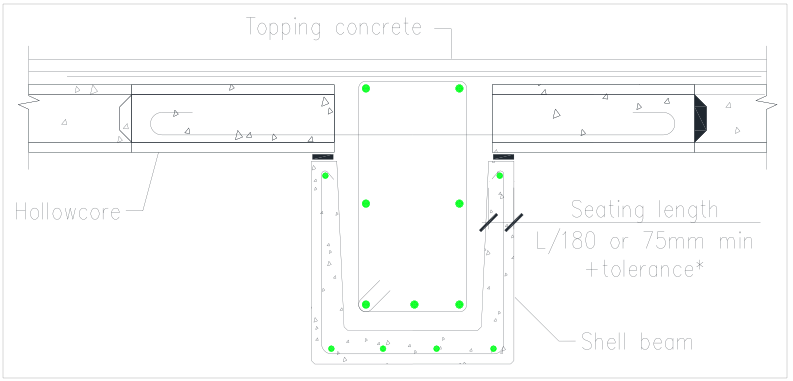

New Zealand has an extensive use of precast concrete particularly on buildings from 1980’s onwards. The use of precast floor units with in-situ concrete topping have almost completely replaced cast-in-place floors and these systems are almost exclusively used in multi-story buildings. Precast floor units are supported by other structural elements inside the buildings, such as beams, wall panels, or block walls. A typical seating detail is shown below.

Typical precast hollow core seating detail on the transverse beam

During the 2010 and 2011 Canterbury earthquakes and the more recent 2016 Kaikoura earthquakes, considerable damage was observed to the precast floor system. One of the failure modes was identified as loss of unit support as the supporting beam elongates and/or spalls, leading to collapse of the unit to the floor below.

Although there were only a few instances of complete loss of support outside of experimental testing, it should be noted that future earthquakes may impose larger demands, such as higher intensities or longer durations, to precast multi-story buildings in New Zealand. Therefore, it is important to assess the compliance of the precast floor unit seatings to the current standard.

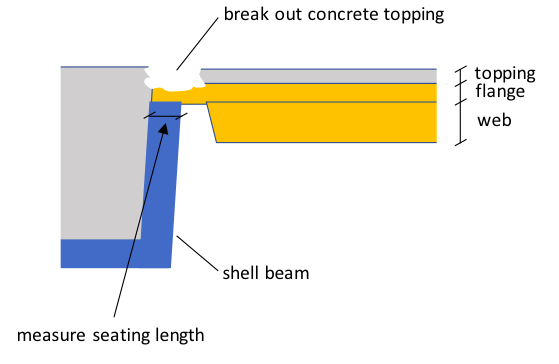

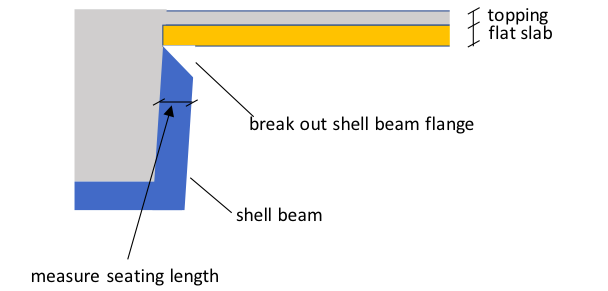

It can be difficult to investigate whether minimum seating lengths are achieved. To date, the only intrusive measure is available for this purpose, by localised break-out of the topping concrete or the supporting beam web, as illustrated in the figures below.

Local break-out on topping concrete to measure seating length

Local break-out on beam web to measure seating length

CSI, as a thought leader in non-destructive testing (NDT) in the construction industry in New Zealand, realises there is a more efficient way for engineers to do this type of assessment. With NDT, there is no need for localised break-outs to investigate the compliance of precast floor unit seating lengths.

CSI is working with Callaghan Innovation to develop an NDT method which can be utilised for this purpose. Without compromising accuracy, the method being developed will expedite the investigation at each location since there is no need of break-outs and subsequent reinstatement, which means more locations can be investigated in day-works. Additionally, it will result in minimum to zero downtime for buildings actively involved in business.

Please contact the team at CSI if you would like more information on non-destructive testing – email: info@csiscan.nz or phone: 0800 33 77 67 and login to our Premium content section online for the full paper on Pre Cast Floor Unit Seating.

Register here for premium content if you are not already a member.

Leave a Reply

You must be logged in to post a comment.